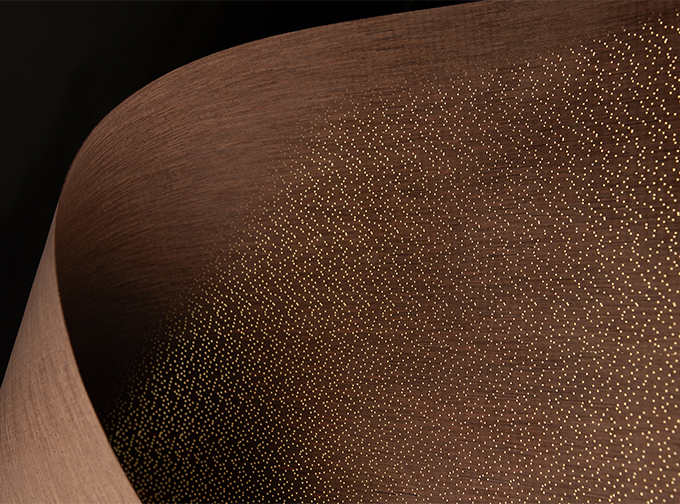

Wood 2.0 – We Live and Breathe Veneer.

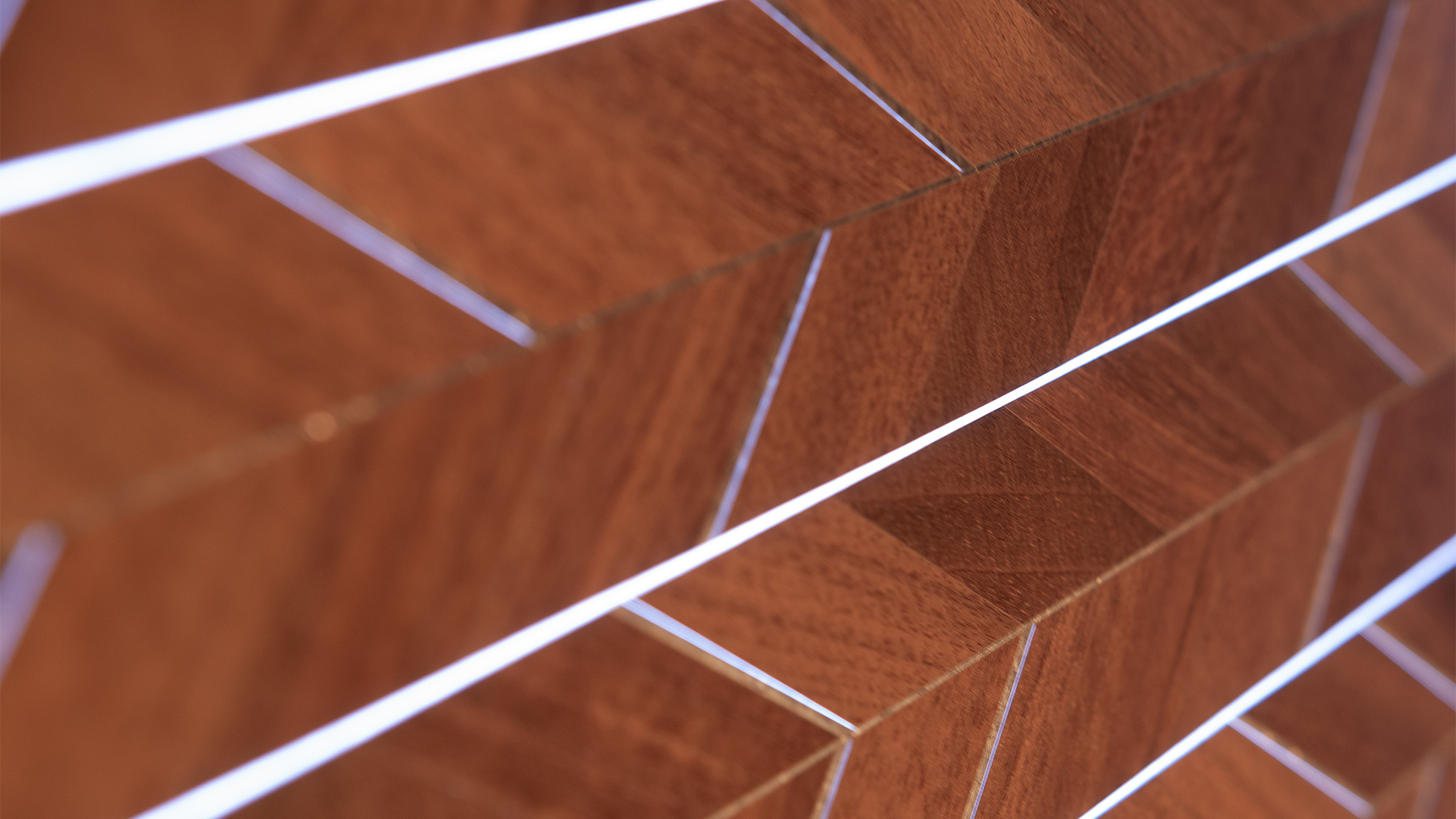

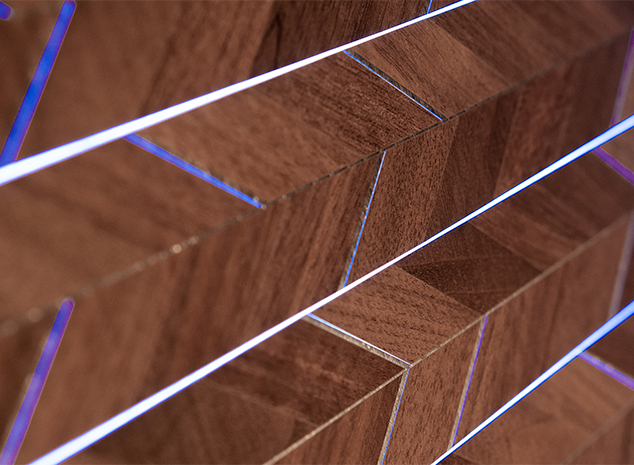

We create exclusive products for our customers from various materials, such as wood, aluminum or recycled materials, which can be used in automotive interiors, yachts, aircrafts and other premium objects. The results of our work are, for example, high-quality center consoles and instrument panels or panels for car doors as well as other furnishings. The unmistakable and excellent design greatly enhances the interior of the object in question, creating a unique atmosphere.

We don’t see ourselves as just a veneer manufacturer. We support our customers in the design process, the development process and at the end of the development we are a reliable partner for series production.

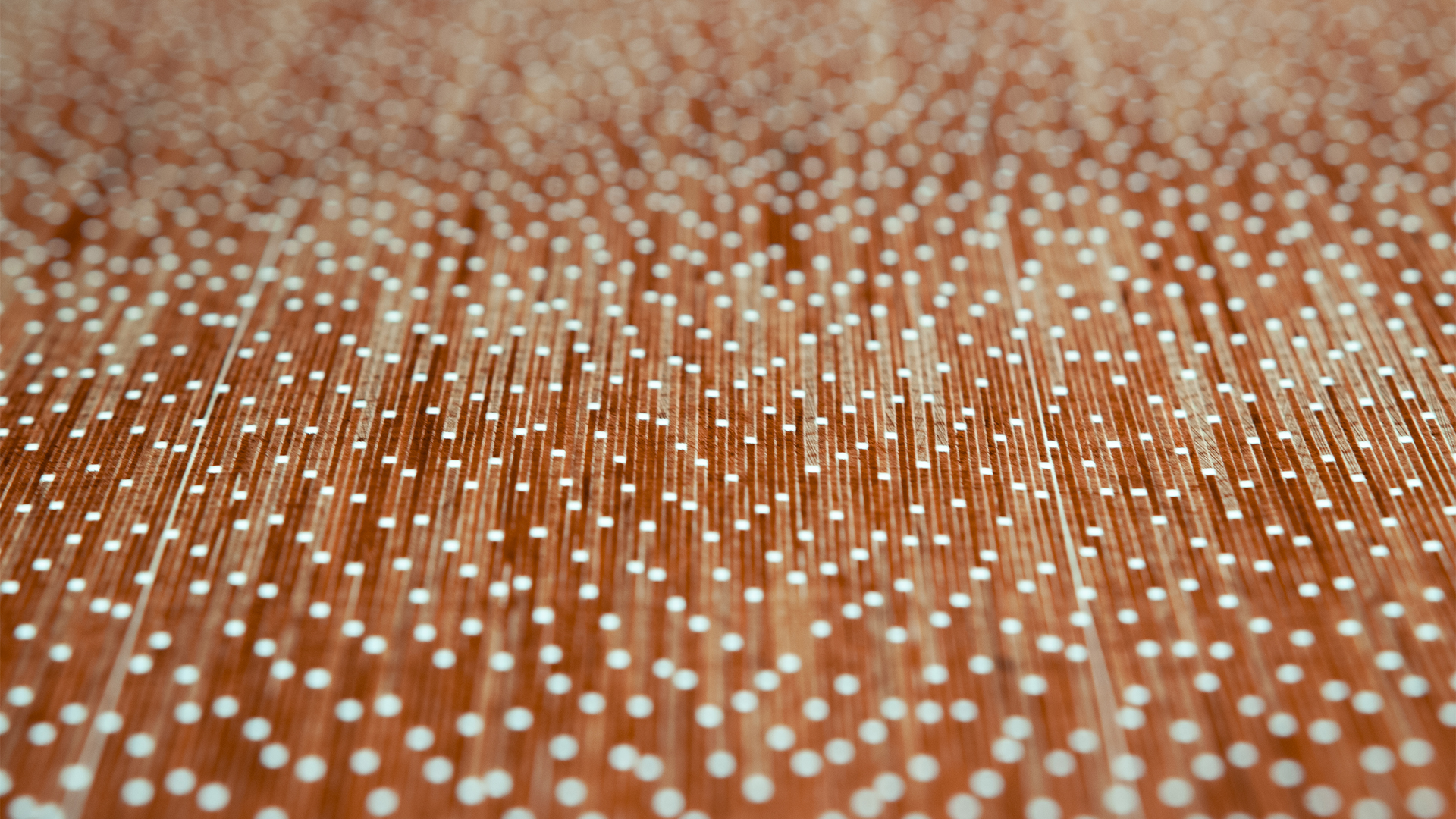

Individuality is very important to us. We manufacture the decors according to customer specifications to the exact dimensions required for the application, so there is no unnecessary waste and resources are saved. Efficient and sustainable production processes are just as important to us as the well-being of our employees and the environment.

As a subsidiary of Fritz Kohl veneer mill, Fritz Kohl Concepts is committed to the task of producing modern decors from real materials. As a veneer manufacturer, we do not shy away from processing new materials that at first glance have little to do with wood. For example, we are able to create a material symbiosis between wood, metal or plastics.

The always very high demands of our customers in terms of both design and product quality continue to drive our innovation process. One of our most important sales markets today is the automotive industry, which always strives for innovation, aesthetics and functionality.