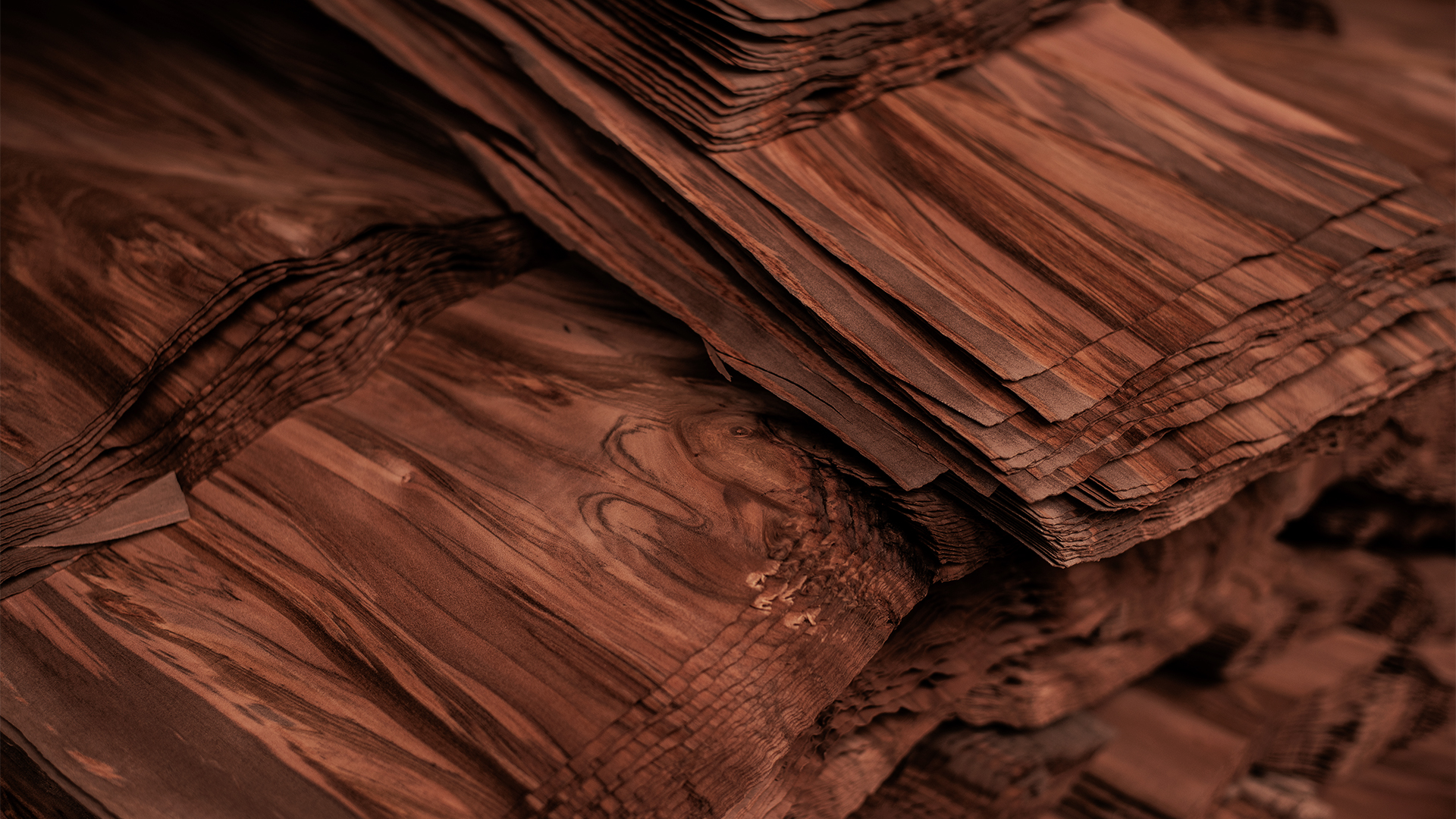

Furniere – das Potenzial des Holzes hervorbringen.

Die Aufarbeitung zu wertvollen Furnieren ist die dekorativste und gleichzeitig ressourcenschonendste Produktionstechnik, um hochwertige Oberflächen aus Echtholz herzustellen.

Zusammengefasst gibt es also folgende Hauptgründe, weshalb der Erzeugung von Furnieren der Vorzug vor anderen, vergleichbaren Be- und Verarbeitungsmöglichkeiten des Rohstoffes Holz gegeben werden sollte:

- Wuchs, Struktur und Maserung des Holzes können beim Fertigungsvorgang optimal herausgearbeitet werden.

- Bei der Be- und Weiterverarbeitung ergeben sich nahezu unbegrenzte Gestaltungsmöglichkeiten.

- Der kostbare Rohstoff Holz wird mengenmäßig höchstmöglich ausgenutzt, natürliche Ressourcen werden geschont.

Furnierherstellung

Moderne Furnierproduktion ermöglicht es, das gestalterische Potenzial des Holzes in seiner vollen Schönheit zu entfalten. Durch präzise Verfahren wie das Messern oder Schälen von Hölzern zu dünnen Furnierblättern wird der wertvolle Rohstoff maximal ausgenutzt, was nicht nur ökologisch, sondern auch ökonomisch von großer Bedeutung ist. Im Vergleich zu Massivholz lassen sich so bis zu 50-mal mehr einzigartige und natürliche Oberflächen gewinnen.

Diese ressourcenschonende Technik eröffnet nahezu unbegrenzte Gestaltungsmöglichkeiten und bringt die natürliche Schönheit von Holz – mit all seinen Farben, Strukturen und Maserungen – perfekt zur Geltung. Jedes Furnierblatt ist ein Unikat, das den einzigartigen Charakter des Holzes widerspiegelt.

Erfahren Sie mehr über den spannenden Prozess der Furnierproduktion und wie wir das Beste aus der Natur herausholen.

Die Aufarbeitung eines Furnierstammes hängt von folgenden Faktoren ab, die bereits im Rundholz beurteilt werden müssen: Geradschäftigkeit, Herz- und Spannungsrisse, Sichtbare Fehler (Äste, Noppen, Faulstellen), Dimension, Farbe, Struktur, Form

Nach heutigen Qualitätsnormen soll eine möglichst fehlerfreie, farblich einheitliche und in der Struktur regelmäßige Fläche erzielt werden. Daher bedarf es langjähriger Erfahrung und viel Wissen über die jeweilige Holzart, um bereits am rohen Stamm die korrekte und optimale Zurichtung zu bestimmen.

Es gib verschiedene Techniken der späteren Aufarbeitung, die jeweils unterschiedliche Oberflächeneffekte des Furniers ergeben. Die sorgfältige und fachgerechte Beurteilung des Rundholzes, auch im Hinblick auf die voraussichtlich erzielbare Qualität sowie den möglichen Verwendungszweck, ist daher essentielle Grundlage der im weiteren Produktionsablauf erzielten Furnierqualität.

Entsprechend der markierten Zurichtung wird der Furnierblock nach dem Entrinden auf der Blockbandsäge aufgetrennt. Die einzelnen Stammsegmente werden anschließend gekocht.

Nach dem Zurichten erfolgt das Kochen der Furnierblöcke. Ausgenommen davon bleiben nur Holzarten, bei denen es auf eine möglichst helle, (fast) weiße Farbe ankommt, wie z. B. Ahorn oder Weißbuche. Durch das Kochen in heißem Wasser werden zwei Effekte erzielt:

- Dem Holz wird die notwendige Geschmeidigkeit gegeben, um einen glatten Schnitt und damit eine einwandfreie Aufarbeitungsqualität zu gewährleisten.

- Durch die Dauer des Kochvorgangs wird die Farbe des erzeugten Furniers beeinflusst. So verändert beispielsweise die ursprünglich weiße Buche ihre Farbe durch Kochen zu einem rosa- bzw. lachsfarbenen Ton.

Abhängig von der Holzart und dem Farbanspruch sind Kochzeiten von einem Tag bis zu einer Woche notwendig. Über den jeweiligen Zeitraum hinweg gibt es zusätzlich für jede einzelne Holzart einen individuellen Temperaturverlauf, der exakt gesteuert werden muss, um Farbfehler zu vermeiden.

Auch die lokale Wasserqualität (Härte, chemische Zusammensetzung) hat erhebliche Auswirkungen auf den Kochverlauf. Daher müssen für jeden Produktionsstandort eigene Zeit- und Temperaturkurven empirisch ermittelt und später penibelst eingehalten werden.

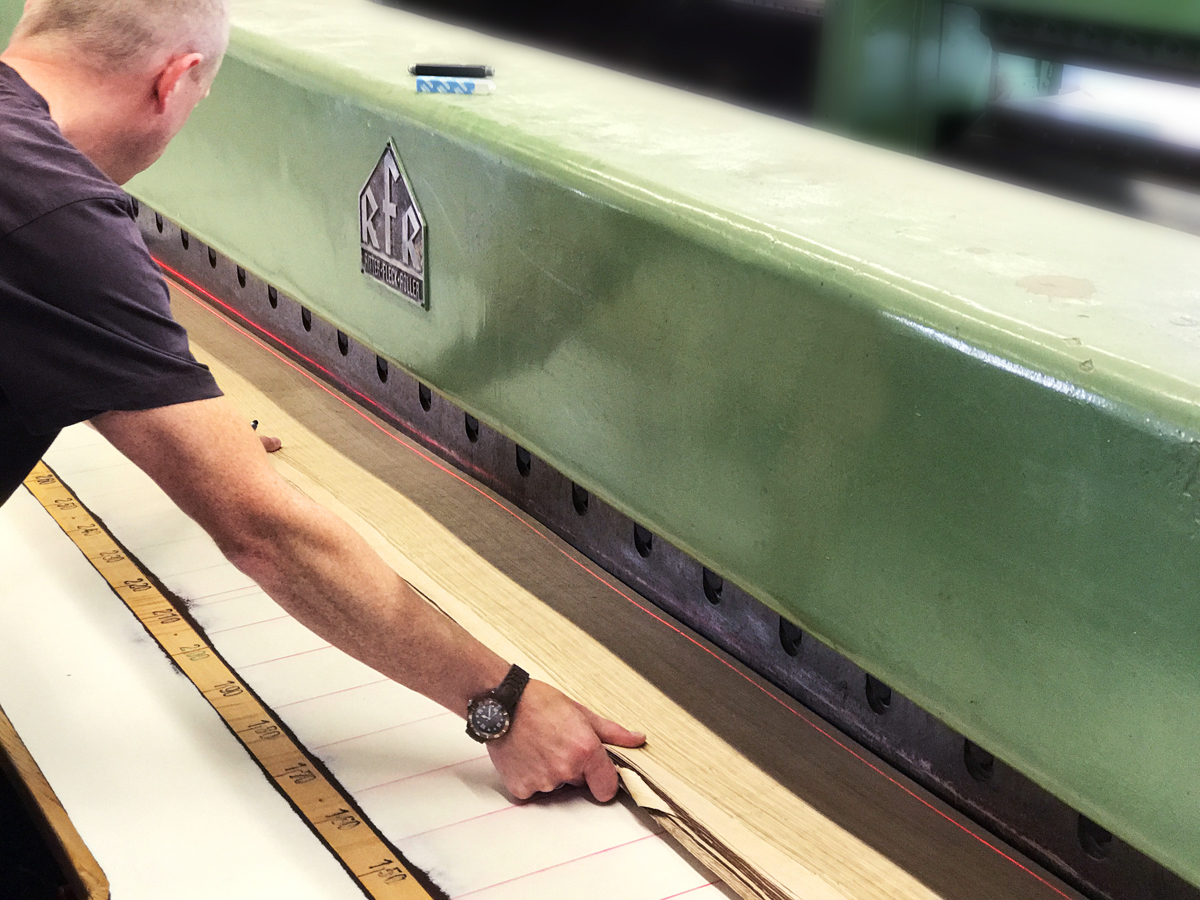

Spätestens hier trennt sich die Spreu vom Weizen. Wo hartes Material mit ungeheurem Druck in feinste „Scheiben“ geschnitten wird, braucht es nicht nur „schweres Gerät“, sondern vor allem erfahrene Mitarbeiter, die mit voller Konzentration und Hingabe für allerhöchste Präzision sorgen.

Vor dem eigentlichen Messervorgang werden die Furnierblöcke zunächst ein- bzw. zweiseitig gehobelt, um eine einwandfrei gerade Auflagefläche auf dem Messertisch zu gewährleisten.

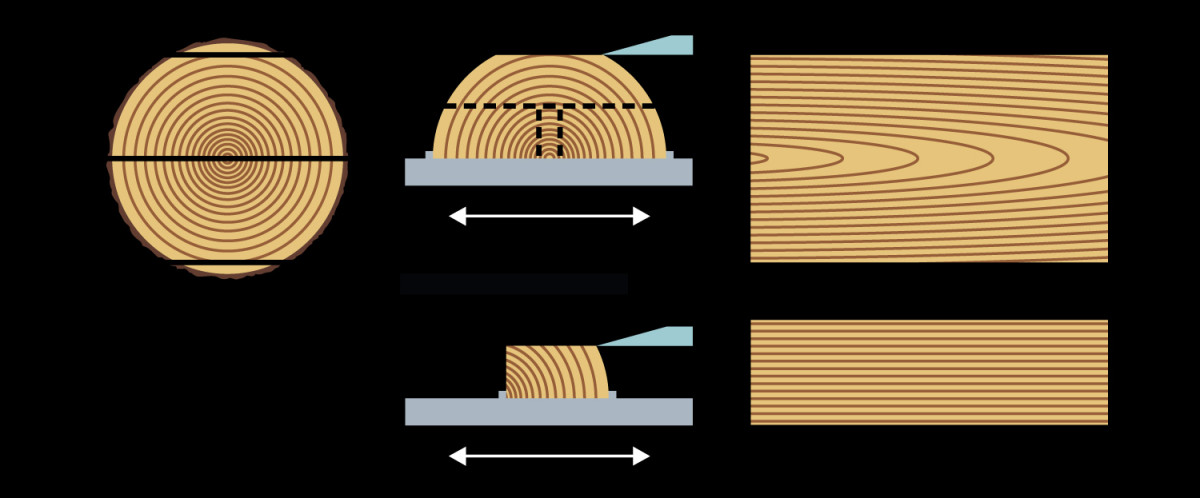

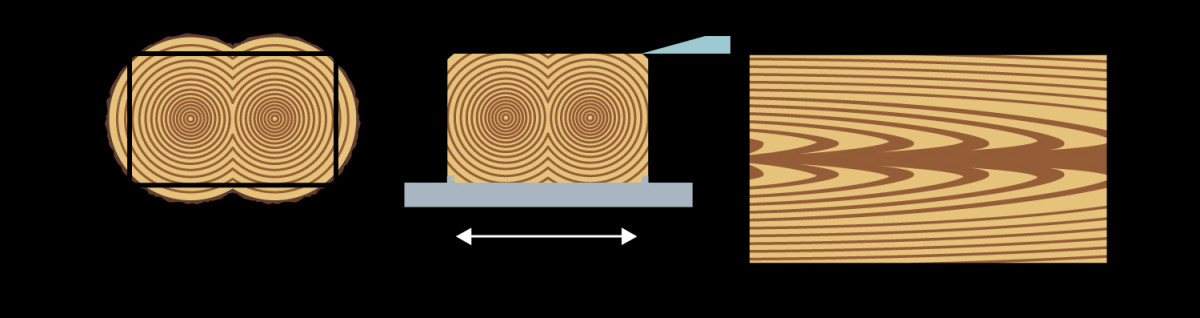

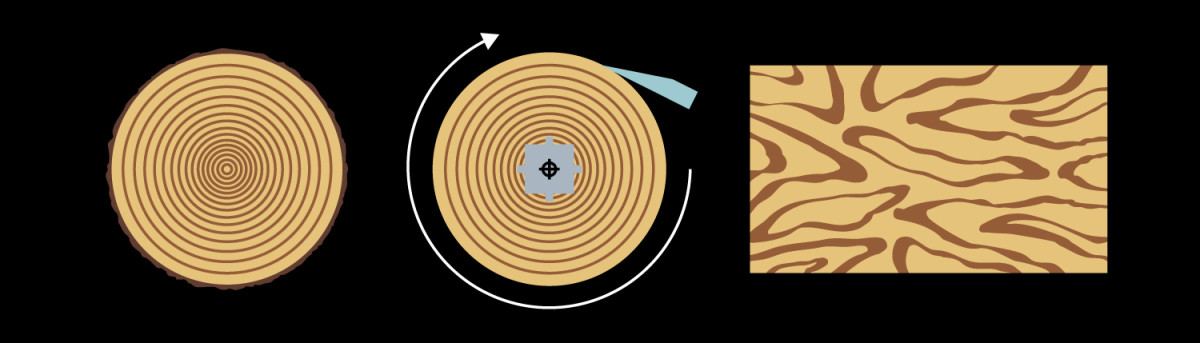

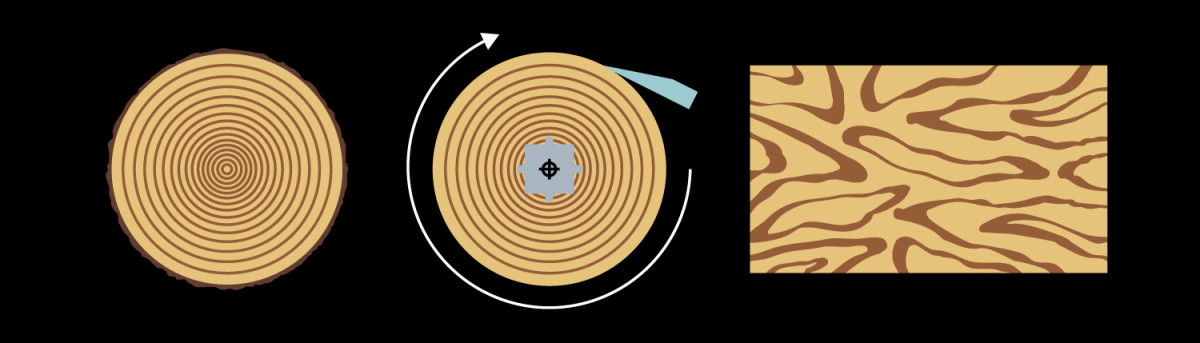

Grundsätzlich unterscheidet man zwei Typen von Furnieraufarbeitungsmaschinen:

- Messermaschine für Horizontal- oder Vertikalschnitt

- Schälmaschine für Rundschälen, exzentrisch Schälen oder Staylog-Schälen.

Je nachdem, welche Maschine und welche Aufarbeitungsart gefahren wird, erhält man gänzlich unterschiedliche Furnierbilder.

Unabhängig hiervon ist von entscheidender Bedeutung, dass Messer und Druckleiste mit einer Genauigkeit von < 0,1 mm exakt eingestellt sind. Nur dann kann eine einwandfreie Furnierqualität erzeugt werden.

Dass dafür das Messer stets eine extreme Schärfe aufweisen muss und, je nach Holzhärte, entsprechend oft nachgeschliffen wird (noch dazu, je nach Holzart, in unterschiedlichen Schleifwinkeln!), versteht sich von selbst.

Bei modernen Messer- und Schälmaschinen wird das zentnerschwere Messer zusätzlich beheizt, um das beim Schnittvorgang ausgepresste Wasser möglichst schnell und gleichmäßig zu verdampfen – so werden Kondensatflecken und „Bläue“ verhindert.

Weitere sogenannte Messerfehler sind:

- Messerscharten: Feine Ästchen (z. B. bei Ahorn), Verschmutzung im oder am Stamm (Sandkörner, Steinchen) oder im Holz eingewachsenes Metall (Nägel, Gewehrkugeln usw.) verursachen Kerben in der Schneide des Messers und damit Scharten im Furnierblatt. Je nach Tiefe der Kerbe wird diese entweder manuell ausgeschliffen oder aber das Messer muss komplett gewechselt werden.

- Wechselnde Stärken: Diese entstehen durch falsches Einhängen des Stammes in die Maschine, durch unsaubere Einstellung der Druckleiste oder durch schlechte Auflage des Holzblocks auf dem Messertisch.

- Trommeln: Regelmäßige, in der Stärke unterschiedliche Rippen, die quer über Teile des Furnierblattes laufen. Gleiche Ursachen wie bei wechselnden Stärken.

Nach dem Messern müssen die noch feuchtwarmen Furnierblätter einzeln getrocknet werden.

Von Maserhölzern abgesehen, sind die strukturgebenden Jahresringe immer relativ konzentrisch angelegt. Würde man nun einen Stamm einfach der Länge nach messern, so ergäben sich im Verlauf der Partie sehr unterschiedliche Furnierbilder, was nicht erwünscht ist. Beim Zurichten wird der Stamm daher in Blöcke aufgeteilt, um möglichst homogene Furnierbilder über den gesamten Stamm zu erhalten.

Diese Blöcke (Ausnahme: Rundschälen) werden mechanisch oder mittels Vakuum-Ansaugung am Messerbalken befestigt, der sich parallel – vertikal oder horizontal – am feststehenden Messer entlang bewegt. Bei Schäl- oder Staylog-Maschinen rotiert der Messerbalken um seine Achse am tangential geführten Messer.

Von der Messerung noch richtig feucht, wird das Furnier auf schnellstem Weg zu einem modernen Düsentrockner – der gleichzeitig einen schonenden Bügeleffekt hat – transportiert. Jedes einzelne Blatt wird – unterstützt von Ansaugvorrichtungen – von Hand eingelegt, am Ende der Trocknungsstraße ebenso manuell entnommen und in Paketen zu je 24 oder 32 Blatt gebündelt, um später das Handling im Furnierlager zu erleichtern. Beschädigte Furnierblätter werden bereits hier aussortiert.

Beim Trocknen werden von Holzart zu Holzart unterschiedliche Programme hinsichtlich Durchlaufzeit und Temperatur gefahren, die natürlich exakt eingehalten werden müssen. Zu trockene Furniere sind brüchig und können nicht weiterverarbeitet werden, zu feuchte Furniere könnten schimmeln und sind dann ebenfalls nicht mehr verwendbar.

Als Richtwert für korrekte Trocknung nimmt man ca. 10–14 % Holzfeuchte.

Da viele Furniere nach dem Trocknen durch unterschiedliche Dichten innerhalb des Furnierblattes zum Welligwerden neigen und früher durch aufwendiges und teures Nachpressen geglättet werden mussten, wurden Bügeltrockner entwickelt, die neben der Furniertrocknung einen sanften Bügeleffekt ermöglichen.

Dieser greift jedoch nur bei leicht welligen Furnieren, stark wellige Furniere, wie z.B. Buche, müssen manuell nachgepresst werden, um problemlos weiterverarbeitet – im nächsten Schritt: beschnitten – werden zu können.

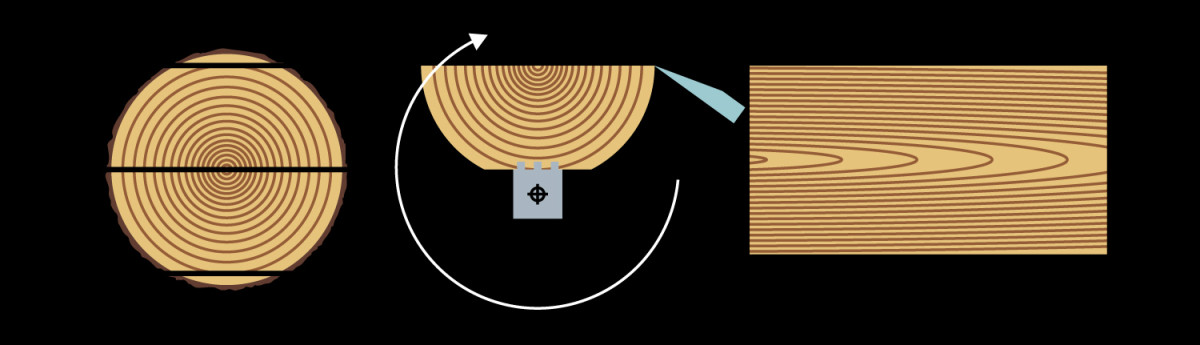

Kaum jemand kann und will Furniere mit unsauberen Kanten verarbeiten, und niemand möchte mehr Quadratmeter bezahlen, als er tatsächlich nutzen kann.

Daher werden die Furniere anschließend von Fachleuten an hydraulischen Furnierscheren zu möglichst rechteckigen Formaten beschnitten.

Gleichzeitig werden Rissbildungen und andere Fehler, wie sie im Kantenbereich häufiger auftreten, entfernt und die Blätter zu Paketen zu je 24 oder 32 Blatt gebündelt, bevor sie taxiert werden.

Nachdem die Furniere den gesamten Produktionsprozess durchlaufen haben, müssen sie taxiert, das heißt preislich eingewertet werden. Bei der Taxierung erfolgt neben der reinen Preisfestsetzung auch die Aufteilung der Furniere in unterschiedliche Qualitäten, wobei alle Parameter in unser Warenwirtschaftssystem eingespielt und elektronisch verwaltet werden – bei einem Lagerbestand von durchschnittlich 8.000.000 Quadratmeter Furnier und 5.500 Kubikmeter Schnittholz wäre es ansonsten eine Herkulesarbeit, genau das richtige Furnier für Sie zu finden.

Generell unterscheidet man:

- Innenausbauqualität

- Schlafzimmerqualität

- Wohnzimmerqualität

- Paneelqualität

- Türenqualität

- Korpusqualität

Holz ist ein höchst individuelles Naturprodukt. Und so sind die genannten Qualitäten weder standardisiert noch genormt. Vielmehr legt hier jeder Hersteller (oder Händler) seine eigenen Regeln hinsichtlich Länge, Dimension und Qualität an, wobei innerhalb der einzelnen Qualitäten auch nochmals in Unterqualitäten unterschieden werden kann.

Was also bei Lieferant A als höchste Qualitätsstufe bezeichnet werden könnte, kann bei einem qualitätsorientierten Unternehmen gerade mal als mittlere Qualität taxiert werden. Da noch dazu jeder Kunde seine ganz eigenen Wünsche und Vorstellungen hat, werden Partien in der Regel vor dem Kauf besichtigt oder zumindest durch die Zusendung repräsentativer Muster qualitativ mit dem Kunden abgestimmt.

Was zuvor allerdings noch ermittelt werden muss, ist die genaue Menge an Furnierblättern, die Dimensionen der Pakete und die Größe der gesamten Partie. Dies geschieht im letzten Arbeitsschritt, der Vermessung.

Was früher eine schier unvorstellbare Mess- und Dokumentationsarbeit war, funktioniert heute vollautomatisch. Die Furniere werden paketweise auf einem Förderband über Photozellen geführt. Diese erfassen auf jedem Zentimeter die exakte Breite des Pakets, vermitteln diese zu einer fairen Durchschnittsbreite und registrieren die Paketlänge. In unserem System werden dann anhand der Durchschnittsbreite, der Länge und der Blattzahl pro Paket die Quadratmeter errechnet und auf der Maßliste ausgedruckt bzw. gespeichert.

Doch damit nicht genug: Jedes einzelne Paket wird von einer kalibrierten Kamera fotografiert und diese Aufnahme zusammen mit allen weiteren Paketinformationen im Warenwirtschaftssystem abgelegt. Dort kann es auf Knopfdruck abgerufen und auch elektronisch an Interessenten übermittelt werden – wenn‘s besonders schnell gehen muss.

Wollen Sie mehr über unsere Herstellungsverfahren wissen? Möchten Sie uns kennenlernen und alles über unsere Expertise in Holz erfahren? Dann schreiben Sie uns!